Description

!!! Click for Price – Stock Information and Purchase !!!

Stainless Welded Pipe

Stainless Steel Welded Pipe,

Stainless Welded Pipes are pipes used in many areas of the industry with and without pressure. Stainless Welded pipes are available as TIG Welded, HF Welded, Laser Welded and MIG Welded. Its raw material is Stainless Steel Coil. Coil sheets are sliced according to the Diameters of the Pipes in the steel service centers. Sliced Coil Stainless steel sheets are bent in machines and turned into pipes by welding with various welding methods. According to the needs of the industry, productions are made according to EN10217-7, EN 10357 (former DIN 11850), ASTM A312, ASTM A249, ASTM A240, ASTM A789, ASTM A790 Norms.

You can use our Live Support Module to get more detailed information about stainless welded pipe prices and features, and you can reach our customer representatives via phone or mail.

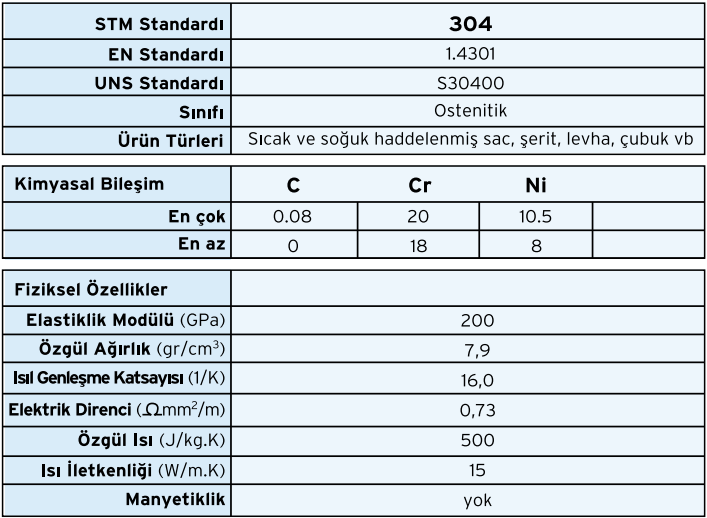

Below are the Technical Details.

Pipe Outer Diameter Range: Ø6mm- Ø 500mm OD

Wall Thickness Range: 0.5mm-5.00mm

Tolerance Class: ISO 1127:D4 / T3 (+-0.5%min +-1.0mm) (+-10%min +-0.2mm)

Test Class: TC1

Surface Treatment: 180-220

Grit / Brushed

Annealing Unit: Full Automatic Bright Annealing

Length Tolerance: (-0) ÷ (+5) mm

Length Range: 3,00mt – 15.00mt

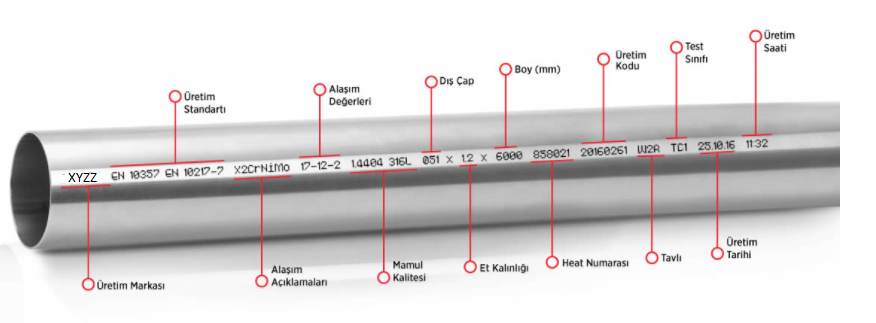

Stainless Steel Pipe Marking is as follows.

1. EN 10217-7: Welded pressure and general use stainless steel pipes

2. EN 10357: Welded stainless steel pipes used in the food and chemical (cosmetic) industry

3. DIN 11850: Welded stainless steel pipes used in the food and chemical (cosmetic) industry (German version)

4. EN 10296-2: Welded (non-method-necessary) stainless steel pipes for general use. This type of pipes are usually manufactured as HF welded for lower cost production.

5. ASTM A778: Welded and unheat treated (non-annealed) stainless steel tubing

6. ASTM A554: Stainless steel pipes used in welded construction. Since these pipes have decorative use, the definition of “Ornamental Pipes” has also been made. They are essentially HF welded low-cost pipes and are definitely not recommended for use in processes.

7. ASTM A358: Stainless steel pipes produced with EFW (electrical fusion welding). During the manufacture of these pipes, each pipe passes the radiography test. (X-Ray Check). In this welding, both edges of the coil sheet are heated to the melting point by means of electrical resistance and the welding process is completed with the help of welding filler without applying any pressure.

8. ASTM A312: Welded (welded) or seamless (drawn) heat-treated, general-purpose stainless steel tubing

9. ASTM A249: Stainless steel pipes manufactured for use in welded heat treated heat exchanger manufacturing

10. ASTM A270: Welded (welded) or seamless (drawn) heat treated stainless steel pipes manufactured for use in sanitary (food – cosmetics – special production pharmaceutical) applications

11. ASTM A269: Welded (welded) or seamless (drawn) heat treated tubings for general use. (usually used in instrumentation applications.)

12. ASTM A213: Tubing used in the manufacture of seamless (drawn) heat treated boiler, heat exchanger (heat exchanger), super heater

13. EN10296-5: Seamless (drawn) heat treated stainless steel pipes for general use and pressure in European norms

14. EN10219-2: It is a welded, cold formed box profile production standard.

15. ASTM A790: It is the standard of welded or seamless ferritic / austenitic (duplex) stainless steel pipes.

16. ASTM A789: It is the tube standard of welded or seamless ferritic / austenitic (duplex) stainless steel tubings.