Description

Stainless Steel Seamless Pipe

Draw pipes are generally used in areas where there is pressure. It is used in piping systems of pressure vessels. The use of fire extinguishing installations is also becoming widespread. It is also used in hydraulic piping systems, machinery and equipment that are moved by the pressure of oil. It is used in heating and cooling systems. For example, the use of Seamless Pipe is common in Kuler construction. The use of heat exchangers is also common, especially in the construction of heat exchangers. It has been seen to be used in the transfer of fluids in the Food Industry. Rusting Drawn Pipes are pipes that are mainly used in high engineering studies. It is also used in Nuclear Power Plants, Chemical and Petrochemical Industries.

In our colloquial language, stainless seamless drawn pipe,

It is called as stainless drawn pipe.

You can use our Live Support Module to get more detailed information about stainless seamless pipe prices and features,

You can reach our Customer Representatives by Phone or Mail.

Stainless Seamless Steel Drawing Pipe ;

Stainless Drawn Pipes are more difficult to manufacture than welded pipes. There are production forms that require many processes. In fact, foreigners also call this type of pipes “tube” “tube” pipe. Tube means that the pipe is not stitched. The production of Stainless Steel Seamless Tubes is heated to a point close to its melting point. Billet Material is ejected in a yellow heated form. Special machines are also drilled inside. After drilling, it is produced by pulling in different machines, forming, reheating and inserting into different form machines, and cooling again and processing. Rusting Drawn Pipe production emerges as a result of very different process applications.

| Production Norms of Stainless Seamless Pipes are as follows. | |

| ASTM A312 | It covers seamless, straight seam welded and heavily machined Austenitic stainless steel tubing designed for high temperature and general corrosive service. |

|---|---|

| ASTM A358 | It covers austenitic chromium-nickel stainless steel pipe welded by electrical fusion. |

| ASTM A813 | Two classes of seam-welded single or double welded austenitic steel pipe cover and alignment grades for high temperature and general corrosive service. |

| ASTM A814 | It covers two grades of flanged and cold bending quality cold-worked straight seam single or double welded austenitic steel pipe for high temperature and general corrosion. |

| ASTM A269 | General Purpose Seamless and Welded Tube Manufacturing from Austenitic Stainless Steel Material |

| ASTM A213 | Manufacturing of Seamless Ferritic and Austenitic Boilers, Superheaters and Heat Exchanger Tubes |

| ASTM A669 | Ferritic and Austenitic Seamless Duplex Stainless Tube Manufacturing |

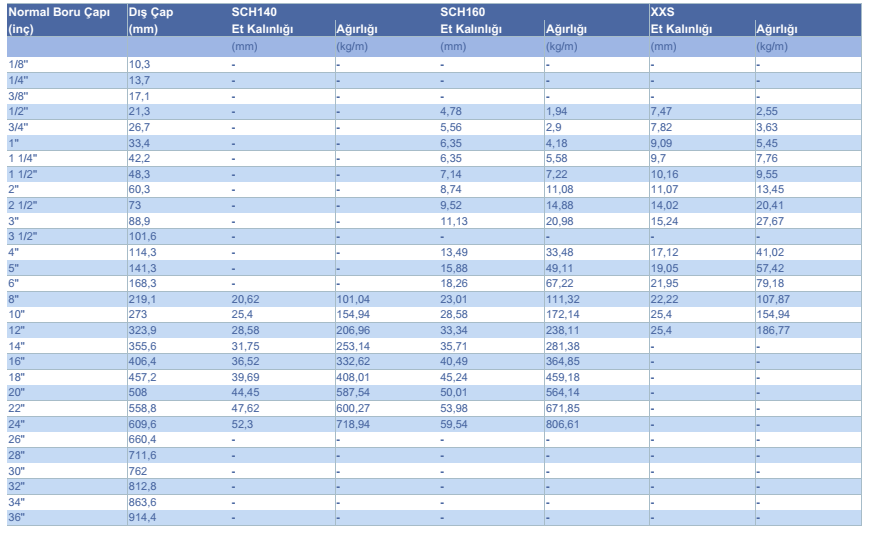

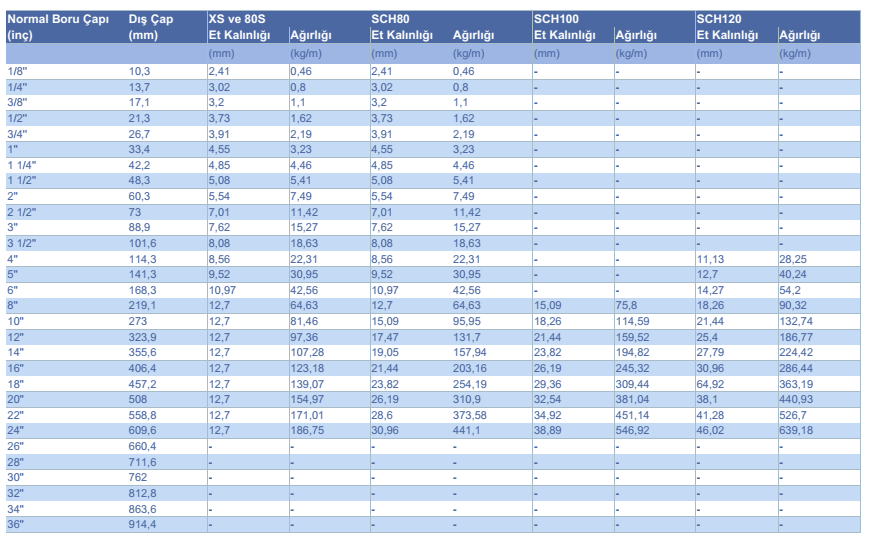

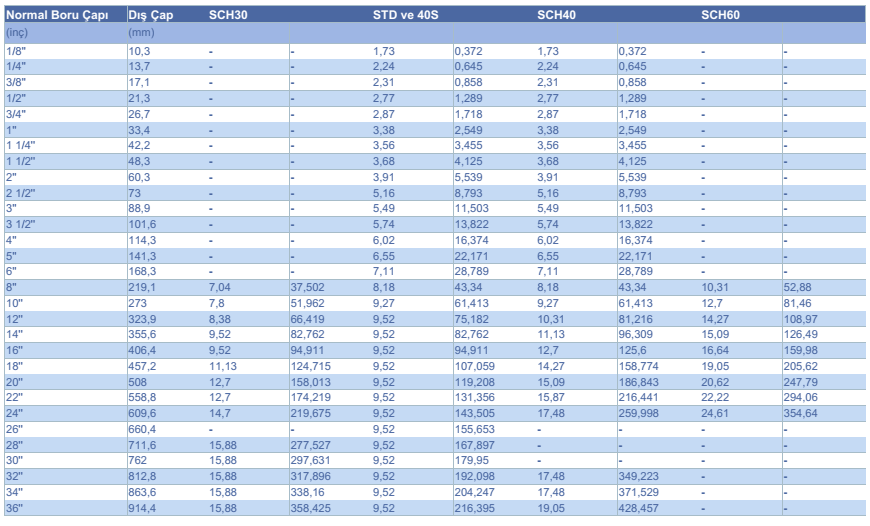

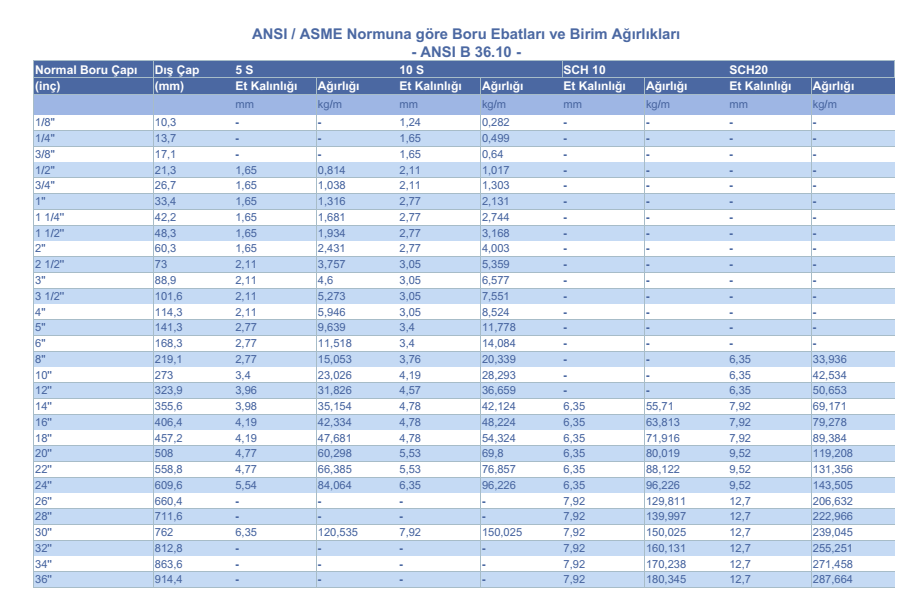

| ANSI 36.19 ANSI B 36.10 | Stainless Welded and Seamless Pipes SCH Series |

Stainless Drawing Pipe Quality Standards,

Seamless/Drawn tube per ASTM A 312 in AISI304 / AISI304L and AISI316 / AISI316L. There are also other stainless quality classes, including AISI304H, AISI316H, AISI309 / S, AISI310 / S, AISI317 / L, AISI321 / H, AISI347 / H, AISI904L, AISI330, AISI254SMO, AISI410. Duplex grades are AISI2205 and Super Duplex AISI2507. There are also other stainless quality classes, including AISI304H, AISI316H, AISI309 / S, AISI310 / S, AISI317 / L, AISI321 / H, AISI347 / H, AISI904L, AISI330, AISI254SMO, AISI410. Duplex grades are AISI2205 and Super Duplex AISI2507.

|

Stainless Steel Drawn | Seamless pipe |

|

| Stainless Pipe Diameters | 1/8 “ to 24” DN6 to DN600 |

| AISI 300 Series Stainless Steel Grades | 304 – 304 / L – 304H – 309 / S – 309H – 310 / S – 310H – 316L – 317L – 321 – 321H – 347 – 347H |

| AISI 400 Series Stainless Steel Grades | 410 |

| Nickel Alloy Grades | Alloy 20 – 200 – 400 – 600 – 601 – 625 – 825H – 825HT – C276 |

Stainless Drawn Seamless Pipe Sizes

STD, XS and XXS

Three long-standing traditional names are used to distinguish pipes of different weights:

• STD : standard wall

• XS : extra strong wall

• XXS : double extra strong wall

The last two designations are sometimes called extra heavy wall (XH) and double extra heavy wall (XXH).